The story behind the SPAM brand’s two-piece can

The SPAM brand, the brainchild of Hormel Foods Corporation, celebrated its 85th anniversary earlier this month on 5 July. Here, Bruce Linebaugh gives a brief overview of the development of the modern two-piece aluminium can used for one of the world’s most beloved food cans today.

The current two-piece aluminium meat can was developed in the mid-1990s by Jim McClung at Can Industry Products (CIP) in Canton, Ohio, along with engineers Paul Ripple and Manuel Rubalcava. McClung was approached by canmakers Silgan and Crown looking into a two-piece rectangular can that would be faster to produce and cost less than the three-piece can that was being used for SPAM and other canned meat products.

McClung and his team began work on developing a deep rectangular can body using the draw-redraw forming process based loosely on a previous design for a shallow non-round can developed for the former Central States Can Company in Massillon, Ohio. This process presented them with several metal-forming challenges, such as determining the optimal shape of the blank that would form the right cup shape to properly draw into the desired rectangular shape can.

The team actually hand-cut the first blanks with scissors which allowed them to experiment with different blank shapes until they determined the optimal one. The final blank shape they landed on is optimised to form the correct shape of cup – this shape is fixed and there’s no latitude with it to produce cups that properly form the rectangular can.

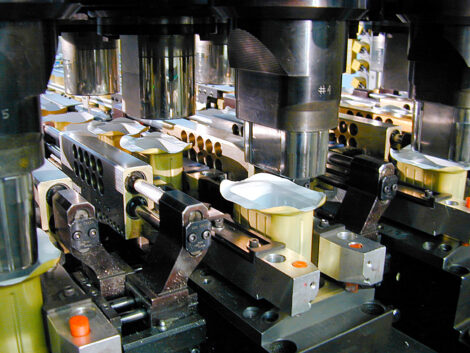

In the cupping press, pre-coated coil stock material is blanked and drawn into the non-round cups. The cups are rotated 90 degrees as they exit the cupping tools and this orientation is maintained as they’re transferred to the redraw press – this ensures that the grain of the metal is correctly oriented to be drawn into the can which is critical to produce a rectangular can.

The redraw press performs three operations: the first operation draws the cup into the rectangular shape at the proper height, and forms vertical beads in the side walls to keep them from collapsing. The second forms the bottom profile of the can, and forms a step shoulder on the top edge where the rectangular easy-open end will be seamed after the can is filled. The third operation trims the top of the can and leaves a perfectly-formed flange for double-seaming the EOE.

The two-piece draw-redraw rectangular meat can developed by McClung at CIP was a revolutionary product that resulted in a more secure, economical and efficiently-produced package for SPAM, and it quickly become the standard meat can used around the world. After the development of the SPAM can, CIP was acquired by Sequa Can Machinery in 1996 (which owned the Standun, Rutherford and Formatec product lines), and Sequa Can was in turn acquired by Stolle Machinery in 2004.

Watch a video of a SPAM can system (the shell press and DRD canmaking system):

McClung retired from Stolle Canton in 2014 and passed away unexpectedly last July at the age of 72. He was a true icon and innovator who left a lasting legacy in the canmaking industry and for the world alike.

Bruce Linebaugh co-heads Dayton-based LineMark Communications based in Ohio, US. The company manages Stolle’s communications channels.